El pasado viernes 27 de septiembre, Industrias Técnicas de Galicia S.A. (INTEGASA), con el apoyo…

NOVEC Project – Innovative condensation / evaporation system with dielectric refrigerant fluid in closed cycle with industrial application-3

IN852A 2018/29

NEWS OF PROJECT EVOLUTION UNTIL JULY 2020

The NOVEC Consortium, formed by four Galician companies, INTEGASA, GIPAT, DOSMASDOS SOLUCIONES INFORMÁTICAS and ATI SISTEMAS with the collaboration of the Energy Technology Group (GTE) of the University of Vigo has continued working throughout 2020 on the physical development of the first NOVEC prototype, focused on a closed evaporative condenser system as part of a refrigeration installation, using the commercial fluid NOVEC as refrigerant fluid.

The NOVEC project was one of those selected in the 2018 “Conecta Peme” call; NOVEC started in March 2018 with a three-year duration and was subsidised by the Galician Agency of Innovation with an eligible budget of 620,117.69 €. Despite the significant impact of the COVID 19 pandemic on the entire economic environment, the NOVEC companies have been able to progress according to the tasks set out in the initial schedule and present themselves in the final phase of 2020 with a prototype undergoing testing.

The aim of the project is to develop a closed evaporative condenser system as part of a refrigeration installation. The refrigerant fluid used for this installation is the commercial fluid NOVEC™, which has characteristics that make it harmless to humans and environmentally friendly. To increase the energy efficiency of the system, the feasibility of implementing various energy recovery systems is being studied.

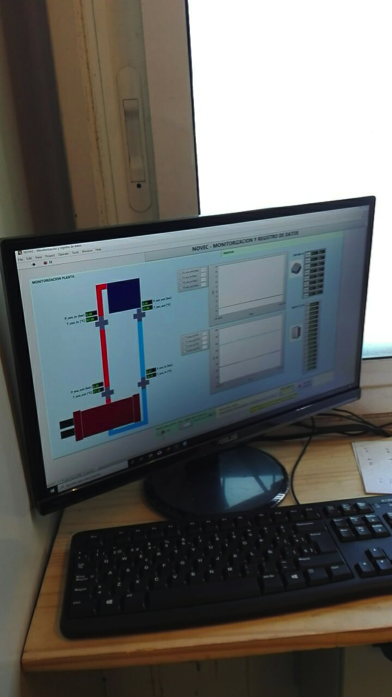

A first prototype of the project is already in the test phase, as planned, in the GTE facilities of the University of Vigo.

These have been the steps taken by the companies to reach the current prototype:

INTEGASA made modifications in the boiling module, expansion vessel and differential pressure sensor incorporated in the fluid chamber.

ATI SISTEMAS has overseen the sensorics and control. Eleven temperature sensors were installed in the plant, as well as a differential pressure sensor in the boiling module.

DOSMASDOS oversees the installation of analogue signal cards; it is also conducting preliminary tests to check the correct operation of the acquisition chain. Work is also being conducted on the monitoring and recording software.

GIPAT, for its part, is currently progressing with the different tests: with grid and with baffle, without grid and without baffle, stability and boiling.