Titanium tubes are used in heat transfer applications where fluids may produce corrosion like sea water and brackish water. Titanium has a high corrosion fatigue limit, and it is resistant to erosion and biological attack.

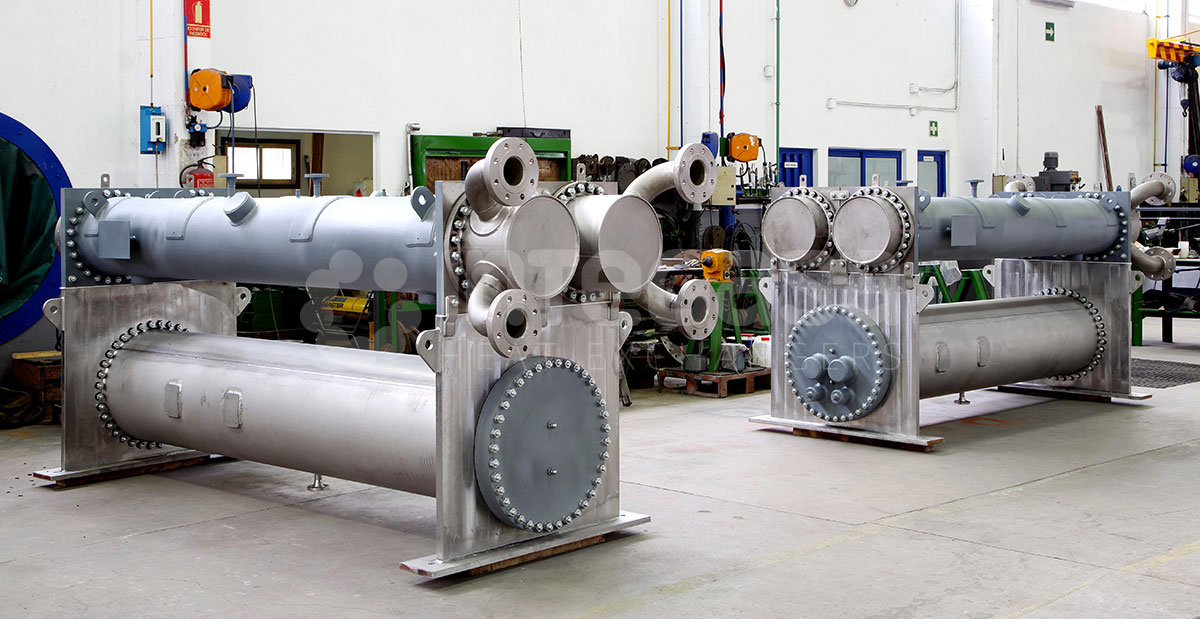

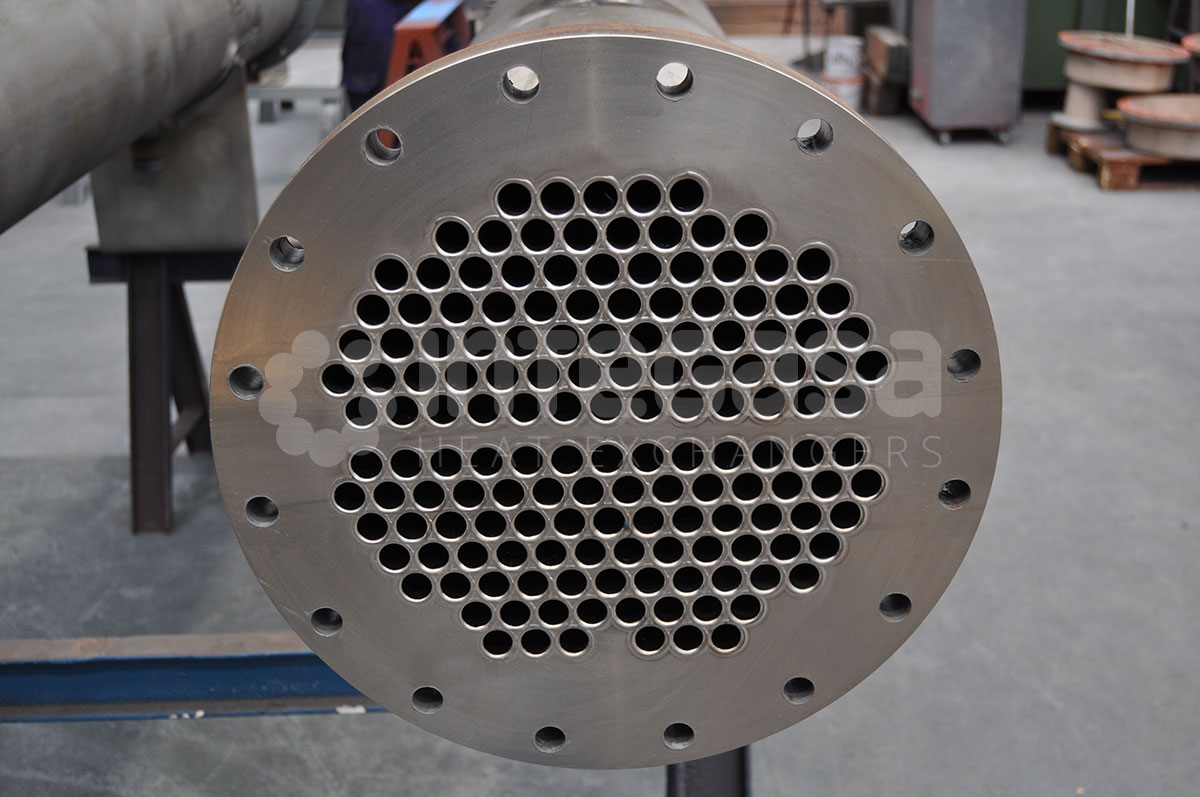

The tubes material is Titanium grade 2, and the carbon steel tube plates are cladded by explosion welding with Titanium grade 1, tube plates are in CS cladded with Titanium and water boxes in CuNi90/10. The tubes are welded to the tube plates by TIG ORBITAL welding process. This tube to tube plate design avoids the corrosion produced when the tubes are only expanded to the tube plates. INTEGASA guarantees the tube to tube plate joint for five years.

INTEGASA designs our equipment with suitable velocities to reduce the fouling factor and to create a self-cleaning effect.

Our standard delivery is eight weeks. Six POLYSOUDE welding machines and our stock of Titanium tubes and Titanium cladded tube plates allow our fast deliveries.

Some examples of Titanium heat exchangers are NH3 condensers, RSW coolers, Spray chillers and Oil coolers. These Titanium heat exchangers are used mainly in marine, Offshore and Oil and gas sectors. Thermal & Mechanical design is done by INTEGASA.