Member of

![]()

University researches and cooperation

![]()

Researching centers cooperation

![]()

MATCHING

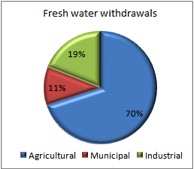

“Materials & Technologies for Performance Improvement of Cooling Systems in Power Plants” is a collaborative Project funded by the EU Horizon 2020 program. It has the aim of reducing cooling water demand in the energy sector.

MATChING is managed by a multi-stakeholder consortium led by Enel and encompassing 16 partners from 6 EU member states.

INTEGASA takes part in this project developing and manufacturing a pilot test condenser to be installed in As Pontes power plant in order to verify in real conditions:

- The improvement of condensation on tubes coated with new materials developed by MateriaNova (Belgium) and the Danish Technological Institute (DTI). The condensation improvement will reduce the water consumption of power plants refrigerating systems.

- The reduction in bacteria growth on tube condensers made with special alloys designed by AIMEN which will open the way to the use of water not valid for human consumption for power plant refrigeration.

INCALSEDO

“Development of technologies for characterization and manufacturing of safe heat exchangers”.

INTEGASA with the cooperation of GTE (Energy Technology Group) of Universidad de Vigo will characterize heat transmission in double wall tubes in order to design new models of heat exchangers with safety against risk of mixing of fluids due to corrosion and vibration. These new heat exchangers will ensure safe supply in sensitive areas like food sector, hospitals, national security and nuclear sector.

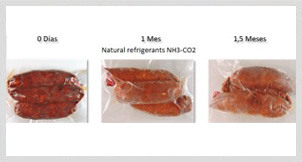

PORCOSOST

“Technologies for Manufacturing and Conservation of Sustainable Food applied to Celta Pig”.

INTEGASA has taken part in this project:

- Designing and manufacturing one frigorific chamber for refrigerated and other for frozen food.

- Designing and manufacturing a frigorific installation using natural refrigerants.

- Developing a predictive system using artificial neural networks for managing of the frigorific installation.

TACTIL

“New Concepts in Heat Exchangers Based in Micro-texturized Tubes with Laser Technology”. A project financed by Program Innterconecta 2016, aimed to develop surface enhanced tubes by laser treatment, to be used in heat exchangers in order to improve the heat transfer.

INTEGASA takes part in this project:

- Designing and manufacturing a test bench to measure and verify the improvement of heat transfer efficiency of the new texturized tubes.

- Designing and manufacturing a prototype of evaporator with the new texturized tubes to be tested by KINARCA in real world conditions.

ROBOFLEX

Development of a flexible and adaptive robotic cell for manufacturing of short series of products with variable geometry for the metalworking sector

EAGRANTS

Development of saving energy technology for maritime applications

INTERSPRAY

Experimental analysis of ammonia and other refrigerants condensation/evaporation on smooth and integral fin tubes

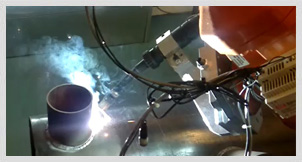

ORBITAL

Design, development and evaluation of an orbital laser welding head for tube to tubesheet joints

COMIC

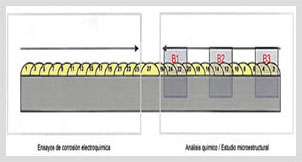

Evaluation and performance of heat exchangers to avoid corrosion

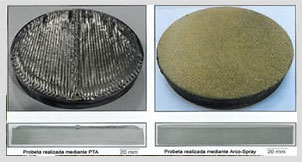

CLAD

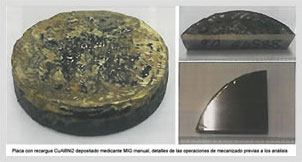

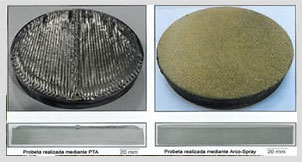

Development of cladding technology using arc welding procedures and thermal projection

TINEX

Development of heat exchangers manufactured in titanium and duplex stainless steel